Cabinet Materials

WWS Typical Materials

Cabinet interiors

Cabinet and Drawer Box Materials

U.V. Finished Plywood- This versatile modified acrylate finish is tough, resisting scrapes, chips and the effects of solvent wipe down. UV Wood panels are the perfect component for a beautiful “real wood” cabinet interior that’s tough enough to handle everyday wear. This is a great option for high end residential cabinetry.

Commercial Grade Melamine- Melamine is an extremely hard resin coating that has been thermally fused to a substrate. This substrate is typically particleboard, MDF, or plywood. Melamine is offered in a wide variety of colors, though most common in White or a light shade of wood. It is very scratch resistant and not susceptible to humidity change.

Finished to Match Exteriors- This option is most commonly seen on furniture, shelving, open cabinets or cabinets with glass doors. This is a wood veneer with a substrate that is typically particleboard, MDF, or plywood. It is then finished to match the exterior of the cabinet. That type of finish is dependent on what was selected for exteriors (see finishing section).

Door Hinges, Drawer Slides & Components

Blum Integrated Soft Close Hinge- Integrated soft close means that there is an on/off switch built into the hinge, so you can decide if the door will have soft close or not and can set the amount that the soft close will assist you. We have used Blum hardware for over a decade as it has proven itself to be the true leader in the industry for cabinet hardware. Blum tests its hinges up to 200,000 cycles - 4 times the ANSI standard.

Blum Full Extension Soft Close Slides- Blum Tandem Slides w/ Blumotion have set the benchmark for the industry as the highest quality slides featured on cabinets to be produced at a very high quality at scale. These slides are great for the residential and the commercial settings. Full extension makes for extremely great access to the entirety of the drawer and built in push/pull adjustment makes slight adjustments extremely easy down the road if your home or facility settles or shifts over time. All drawers made within our standard cabinet sizes (36” or less) will be rated for over 100# load limits per drawer. Blum tests its slides up to 100,000 times – twice the ANSI standard.

Blum 7/8 Extension Soft Close Slides- These slides are the exact same slide as the slides listed immediately above, the only difference is that they offer a 7/8 extension as opposed to a full extension. To be accurate it is actually beyond 7/8 extension, so the difference is extremely minimal. The reason that we use these is because they are more economical than the full extension while still providing a great quality slide. These slides have became our standard for our Pembina Trail Cabinet Line and our Multi-Family or Unit Cabinetry.

Cabinet Leg Levelers- WWS standard construction comes with cabinet leg levelers for each base cabinet (4 legs per typical base cabinet). These leg levelers allow for precise adjustment of cabinetry and casework, a press fit connection to provide extra strength and stability (600 lbs per leg) and various height adjustments are able to be offered. All plastic used for these legs are made from ABS material. The decorative toe kick to match the cabinet exteriors is fixed to the face of these legs.

Cabinet Exteriors

Face Frames, Composite substrates for painted products & Woods

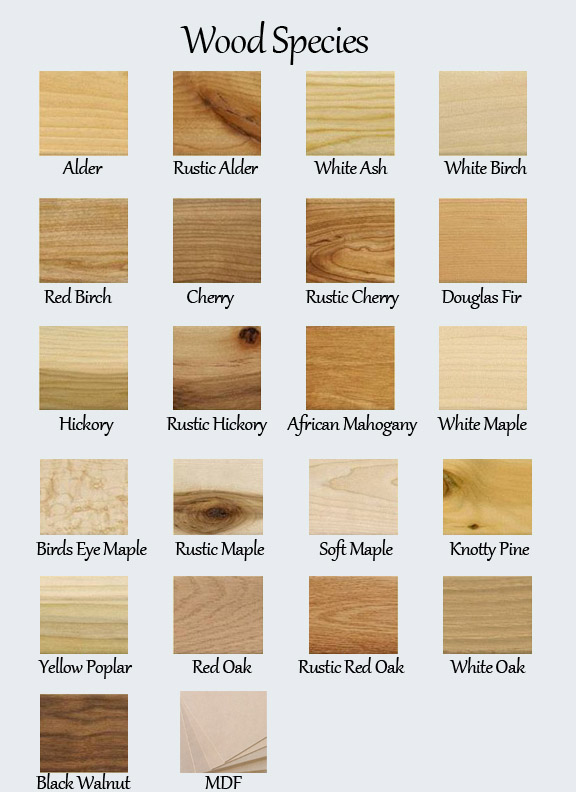

Hard Woods- Hickory, Ash, Cherry, Red Oak, Walnut, Maple, Elm and White Oak are the most common dense woods that we use for our wood cabinet faces and frames. The more dense woods like these, tend to be more durable to the end user and much less susceptible to scratches and scuffs. Many of these woods are available in the rustic version that will have knots and character present, and many of these are also available in more specialty cuts such as Rift Cut and the Quarter Sawn options of each species. You can see the chart below for some of the woods offered and stocked at WWS and we always carry a wide variety of samples at our showroom.

Soft Woods- Alder, Poplar, Pine, Birch, Soft Maple, Aspen and Fir are some of the less dense woods that we use at WWS. These woods typically make for a more economical selection. They also often offer a very unique rustic look when if you keep the knots present on the finished product. You can see the chart below for some of the woods offered and stocked at WWS and we always carry a wide variety of samples at our showroom.

Face Frames- For our typical cabinet that is constructed with a face frame, we use lumber that is made from the same species of wood that is selected for the exteriors of the project. it is typically 7/8” Wide and covers a 3/4” box edge unless it has built on scribe added to the frame for purposes that involve clearance, layout, installation etc. While the face frame offers additional and structure and strength to a cabinet, it has become less popular in the last few decades due to aesthetics and obstruction of access. WWS has found a great way around this as we offer a very petite face frame that rarely (unless needed for support) has a center stile, and our frames offer very minimal overhang on the inside or outside of the cabinet box itself. We still use the face frame as our standard since it offers extreme durability and strength for years to come.

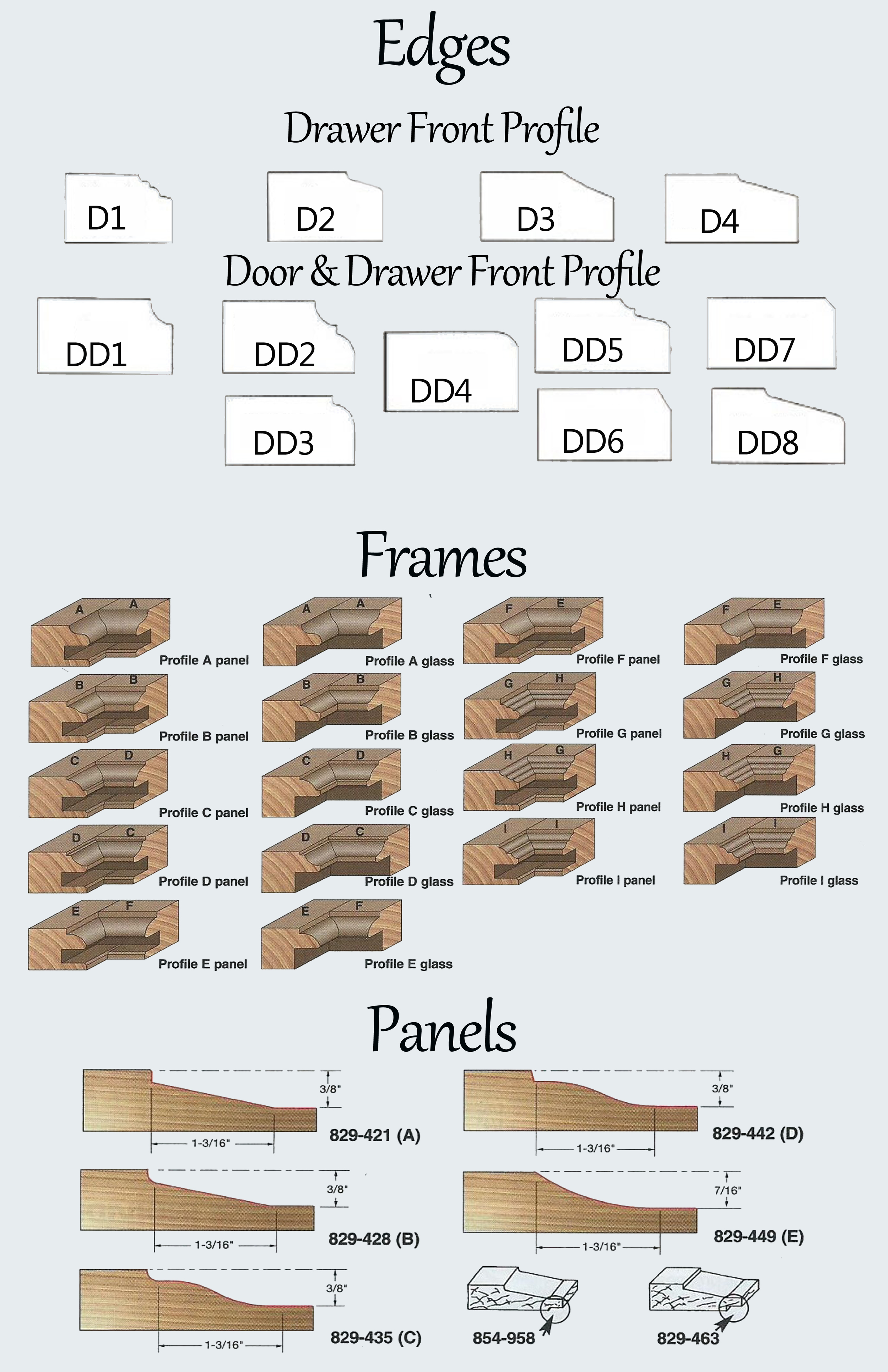

Edging- We apply Poly Vinyl Chloride Edges to our shelves, cabinet bottoms and exposed box edges of our frameless style cabinetry. We use modern high-quality equipment to apply these edges in order for these products to produce the best bond possible. We also apply veneer and melamine edging in a similar manner. These edges typically come in an option of .018 and 3mm thick. We also apply lumber edging on shelving and wood tops. this is typically 3/4” thick.

Material for Painted Doors and Drawer Fronts- The standard construction of doors and drawer fronts for “painted” (Pigmented Pre-Catalyzed Lacquer) is done out of a product called HDF. HDF is an abbreviation for High Density Fibreboard. HDF (High Density Fibreboard/Hardboard), sometimes referred to as HDF wood, is like MDF in that it is a man-made composite panel product that is manufactured from compressed wood fibres. It is a much stronger, harder, and more dense product than MDF however and carries a typical density of up to 900kg/m3. The reason that we use HDF for our painted cabinet exteriors, is because unlike wood. HDF is not susceptible to humidity and moisture changes. Wood products will shrink and expand as moisture levels in the air fluctuate. As they shrink and expand, weak points in the door or front may have a tendency to show hairline cracks. By using HDF we eliminate this by using a product that is much more moisture stable, but also by using a product that can avoid weak points by using a solid door as opposed to the typical 5-piece cabinet door. The only drawbacks from HDF to MDF is that the cost is greater and it is slightly slower for us to work with, from our standpoint, even with these being noted HDF is far superior for use when it comes to painted cabinetry.

Doors, Drawer Fronts, Crown & Handles

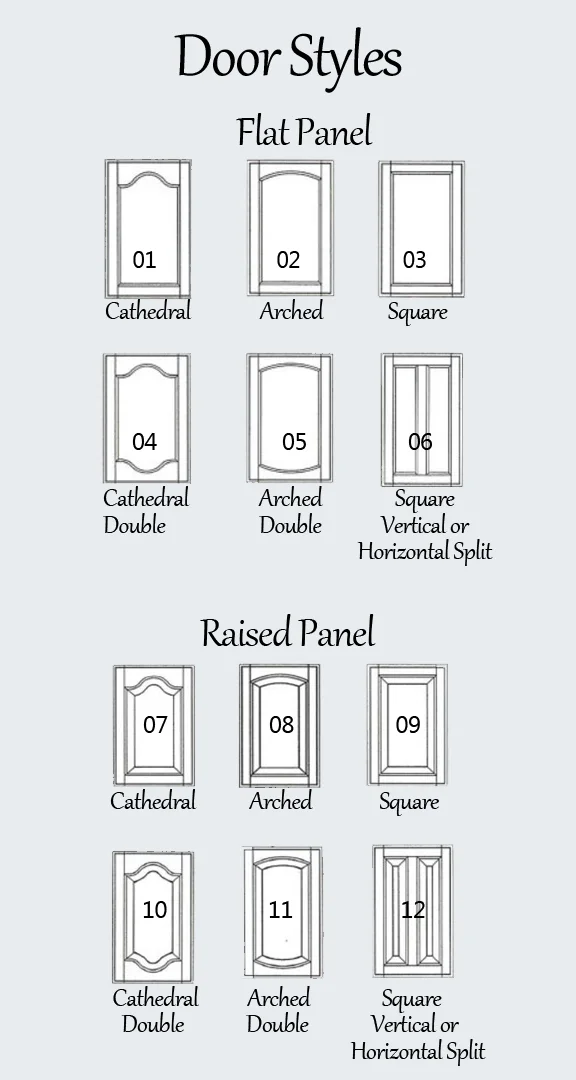

Shaker- Our standard Shaker Door or front is a 2 1/4” Wide Stile and Rail with a 1/4” thick inset panel. On a true Shaker, there is no inside or outside profiles, they are left square and lightly eased.

Mission- The WWS take on a Mission door or front is that we keep the 1/4” thick inset panel but offer any number of variations to the stiles and rails. One common variation is to go with a wider door frame, such as having 3” Stiles and Rails as opposed to the standard 2 1/4” that you have with Shaker. More options include going with your typical Shaker style, but having an inside and/or outside profile of your choice.

Square Raised Panel- The Square Raised Panel has the same options for the outside frame (Stiles and Rails) as the Mission Door/Front, but the inside panel is raised to the same thickness as the frame (3/4”). There is a number of panel options to choose from and you can see those options below.

Arched Raised Panel- The Arched Raised Panel is simply referencing the type of arch on the panel and door frame. Arches were once extremely popular and may be again, but for the time being, we rarely see much come through for arches other than simple arches on the upper cabinets.

Slab- Slab is referring to a flat, modern style door or drawer front. You can have an outside profile with this, but it is typically displayed with a square edge. people tend to like this look as it is sleek, modern, doesn’t collect dust and lets the wood or color do the work as opposed to the design of the door or front.

Slab Laminated Doors and Fronts- For our standard slab P-Lam Doors and Fronts, we use a substrate for the core, Plastic Laminate for the exterior and either Plastic Laminate or White Liner (Plastic Laminate) for the interior (per spec.) and the edging is as spec'd per the job and will vary between .018MM and 3MM. We also have access to color core for the edging. For laminate supply we carry Wilson Art, Formica, Green Lam, Pionite, Nevamar and have access to many others upon request.

TFL Slab Doors and Fronts- Our TFL slab doors and fronts are very similar to our commercial style doors, however we are limited to the color selection that TFL has to offer. Another variance is that while our commercial style slab doors have a surface adhesive applied before being pressed together to form the bond, Duramine laminate is thermally fused through the entirety of the core (substrate) the the exterior laminates of both sides. This makes for an extremely aggressive bond that is virtually inseparable without splitting the actual substrate. These types of doors can be used on some commercial projects with minimal architectural specs and on our Pembina Trail line of cabinetry at WWS.

Crown- See our most popular crown options below. We are not limited to these options; these are simply our most commonly used crown moldings. Our 3-piece crown can be interchanged between Shaker and Victorian

Handles & Knobs- We have a large selection of cabinetry hardware at our showroom and an even larger selection online. Here is some of the links to our more popular brands. Amerock- Cabinet Hardware | Amerock Hickory- Hickory Hardware Cabinet Hardware Company

Finishing-Custom finishing by nature is an art that is a very involved process for everyone involved. Due to the amount of work that we do, we have great systems in place that work well for both us and our customers. Everything we finish at WWS is completely custom mixed from base colors. We have acquired an extremely large catalog of work and can reference a huge number of projects that will be able to get us close to what you are in search of and we will not stop until we can get the color just as you want it.

We have a large selection of colors at our showroom that we have used in the past for reference or if you have seen a color that you want to have, just show us an image or sample and we will start sending you samples until we get it just the way that you want it. Each wood will have different attributes etc., but we will gladly explain all of that to you during our time together.

While we no longer use “paint” and instead use a product called pigmented catalyzed lacquer, we still often refer to it as paint for customer familiarity. For our “paint” colors, we have access to every color from Sherwin Williams and Benjamin Moore as well as the ability to match any color that we can get a swatch for.

We use a H20 based stain and an H20 based Catalyzed laq. for finishing our wood products at WWS. There are numerous benefits to Water borne finishing products for the manufacturer but more importantly for the end user of the product. We were not able to make this switch until recently as the H20 based finishes were not on par with other bases of finish and we were not willing to sacrifice our product, but through extreme research and development we now have a complete H20 based finishing system that we can be proud of the quality while feeling good about the safety benefits to our employees and customers.

Crown Molding Styles

Shaker Style Crown

3-Piece Crown (Shown in Shaker)

Victorian Crown

Flat Board Crown

Door & Front Profile/Panel Options

Cabinet Box Interiors

White Melamine Interiors

Maple Melamine Interiors

U.V. Plywood Interiors

Overlay/Inset Doors

Overlay Door

Inset Door

Cabinet Hardware Selection

Door Appliques

Glass Doors w/ Mullion & W/ Out

Shaker Door Applique

Drawer Front Styles

Inset Panel W/ S.R.O ISP & OSP

Slab W/ S.R.O. OSP

Slab

Raised Panel W/ Ogee ISP & OSP

Door Styles

Mission Style 3” Stiles & Rails Slab

Square Raised Panel- Beveled Panel, Ogee ISP, R.O. OSP

Square Raised Panel- Coved Panel, Ogee ISP & OSP

Shaker

Simple Arched Raised Panel- Ogee Panel, S.R.O. OSP & ISP

Square Raised Panel- S.R.O. Panel, S.R.O., ISP & OSP